Data-based scale-bridging simulation of structured magnetorheological elastomers

Subproject description

The aim of this subproject is to investigate the process-structure-property relationships of structured magnetorheological elastomers (MRE), where the particles are anisotropically arranged within the polymer matrix. These structures are formed by external magnetic fields during fabrication.

In collaboration with other subprojects, the relevant physical processes from production to final material are experimentally analyzed. The findings will be prepared for educational purposes and made accessible to the public through outreach activities.

The focus is on developing model- and data-based methods for multiscale simulations of MREs. Numerical homogenization methods are employed to infer the macroscopic material behavior from constituent properties and microstructure. Computed tomography data of real microstructures are statistically evaluated to construct statistically equivalent volume elements (SVE) with a reduced number of particles. This homogenization reduces computational effort and allows for the examination of the relationship between process parameters and magnetomechanical properties.

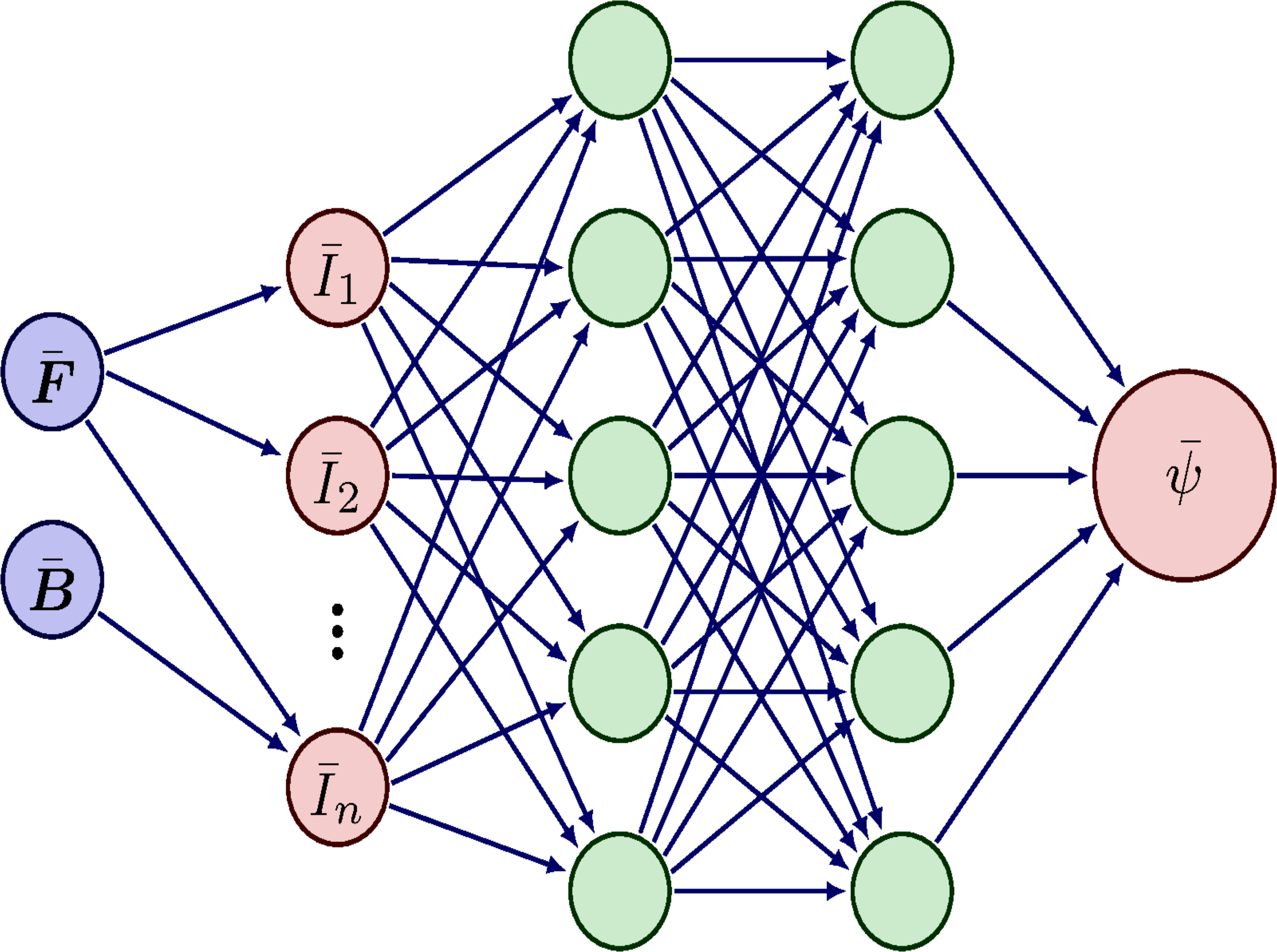

A macroscopic material model for MREs is formulated based on physics-augmented neural networks, which combine the advantages of classical material models with the flexibility of artificial neural networks. This enables the analysis of the behavior of samples and actuators under various loads. The goal is a deep understanding of the micro-to-macro scale interplay. Looking ahead, automated frameworks for autonomous material design and the extension of models to include dynamic effects will be developed.

The writing of this text was assisted by AI - view original